Wire and cable selection is one of the most overlooked yet critical steps in any project. Whether you’re wiring a new facility, building equipment, or sourcing for defense applications, choosing the right cable ensures efficiency, safety, and long-term reliability.

Step 1: Understand the Application

Every system has its own electrical, environmental, and mechanical needs. Ask yourself:

- What is the voltage and current level?

- Will the cable carry power, control, or data signals?

- What’s the operating environment—indoor, outdoor, corrosive, or high-temperature?

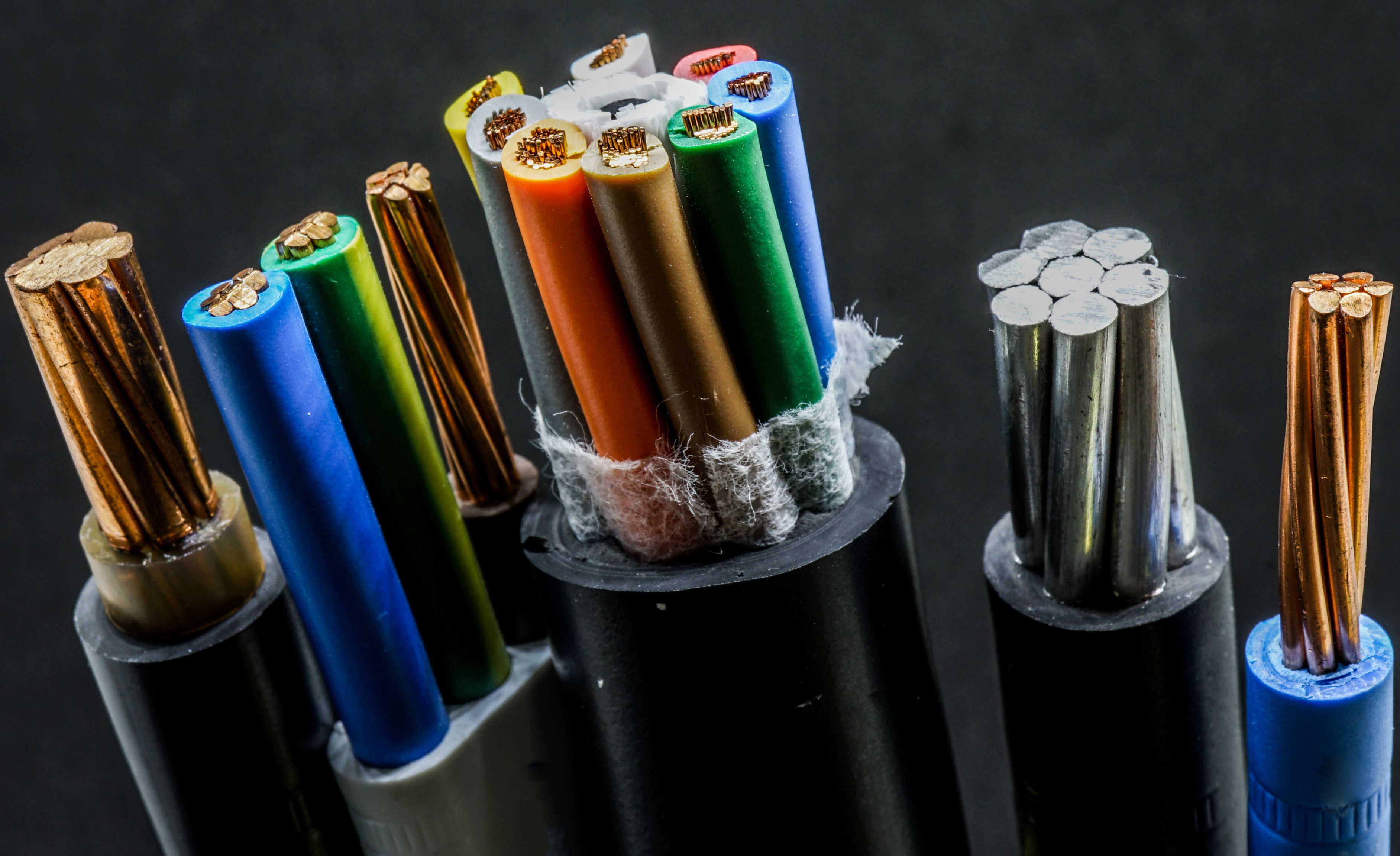

Step 2: Choose the Right Conductor

- Copper: The standard for conductivity and flexibility.

- Aluminum: Lighter and cost-effective for power distribution but less flexible.

- Tinned Copper: Ideal for moisture-prone environments or marine applications.

Step 3: Insulation & Jacketing

Insulation protects the conductor; the jacket protects the cable as a whole.

Common materials:

- PVC: Economical, flame-retardant, suitable for general use.

- XLPE: Excellent electrical properties and higher temperature resistance.

- Teflon (PTFE): For harsh chemical or high-temperature conditions.

Step 4: Environmental Factors

Temperature extremes, chemical exposure, UV light, and mechanical stress all influence cable longevity. Match insulation type and thickness to these factors.

Step 5: Compliance & Certification

Always verify compliance with NEC, UL, or MIL-SPEC requirements, depending on your industry. Certified products reduce inspection risks and ensure consistency.

Step 6: Consult the Experts

Even experienced teams benefit from supplier guidance. Imperial Wire & Cable helps customers interpret specifications and balance performance with cost.

Key Takeaway

Choosing wire and cable is a technical decision with financial consequences. Work with a trusted distributor who understands both sides—engineering and procurement.